Full-scale set-up for removal micropollutants

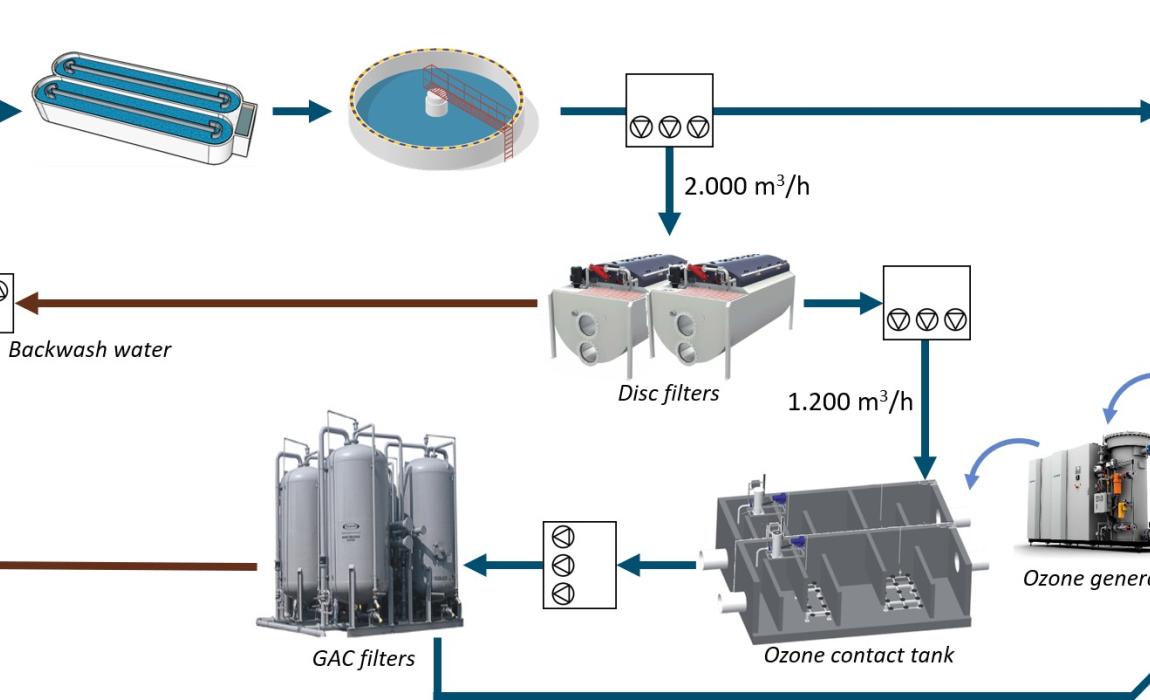

At the Aartselaar sewage plant, work has started on the construction of a full-scale set-up for the removal of harmful micropollutants. This after-treatment of purified waste water (effluent) involves a combination of two tried and tested techniques: an ozone treatment and a treatment based on activated carbon. The monitoring campaign started back at the end of May in partnership with VMM (the Flemish Environment Agency) with a view to a relevant baseline measurement, a reliable basis for further analyses. The installation should be operational from summer 2023.

Micropollutants – even in low concentrations – can have a negative toxic effect on the environment. That is why VMM and Aquafin have started to construct an installation to remove micropollutants. The installation in Aartselaar will combine two tried and tested technologies that are already being used in Switzerland, Germany and the Netherlands, some of the leading countries in research into micropollutants: Ozone treatment and a treatment based on activated carbon. Ozone breaks down micropollutants while with activated carbon, the substances stick to the carbon which is then regenerated. However, these techniques also have drawbacks. For instance, the ozone treatment is a real energy-guzzler: it takes a great deal of energy to produce ozone and to direct the ozone through the water via aeration. Then the drawback with carbon is the ecological footprint as the micropollutants adhering to it have to be removed from the carbon again at high temperature.

The installation in Aartselaar will combine these two techniques. That will allow us to use lower doses of ozone because the activated carbon will capture the remaining micropollutants. A lower ozone dose means less energy consumption and because of the fact that some of the micropollutants have already been broken down in the first ozone stage, the carbon has less to do, lasts a lot longer and therefore high-temperature regeneration is required less often.

The waste water will go through the traditional purification process first of all before some of that purified waste water is subjected to additional after-treatment using the ozone and activated carbon. Annually, we will be able to carry out after-treatment to remove micropollutants on around 75% of all the waste water that ends up at the sewage plant in Aartselaar.

Measurement is the key to knowledge

VMM and Aquafin are planning a major monitoring campaign with two clearly defined objectives: On the one hand, we want to clearly map the efficiency of the treatment plant (what happens after each stage, what happens if we adjust certain parameters, etc.), and on the other hand, we are going to look at the effect of the after-treatment on the quality of the water in the Grote Struisbeek, the water course into which the effluent is discharged. The samples for analysis will be taken at various relevant points within the purification process on a monthly basis.

You can actually plot the way in which you measure micropollutants and toxicity on a horizontal axis. On one side, you have the chemical substance and on the other side the visual effect, with the reactions that determine how you get from substance to end result in-between. By taking such broad measurements, we will be able to get a really good overall idea of the effect of the installation on aquatic life.

The various samples will be analysed in different laboratories, including VMM’s laboratory and Aquafin’s laboratory and three external laboratories: the Provincial Institute for Hygiene, ECCA and Bio Detection Systems, a laboratory from the Netherlands.

And in the future?

Aquafin wants to be well-prepared when the obligation to remove micropollutants comes into effect. In the meantime, the installation and associated monitoring campaign here in Aartselaar will be able to teach us a lot. A great deal of flexibility has been built into the after-treatment (such as the retention time of the water, dosing, etc.) so that we will be able to make adjustments really easily and efficiently. As far as the construction of future installations – bigger or smaller – etc. is concerned, we will take the results from Aartselaar as a basis. The comprehensive monitoring campaign will be able to tell us which measurements can actually teach us something and how often these measurements should be carried out: all questions that we want the installation in Aartselaar to answer.